Maelezo

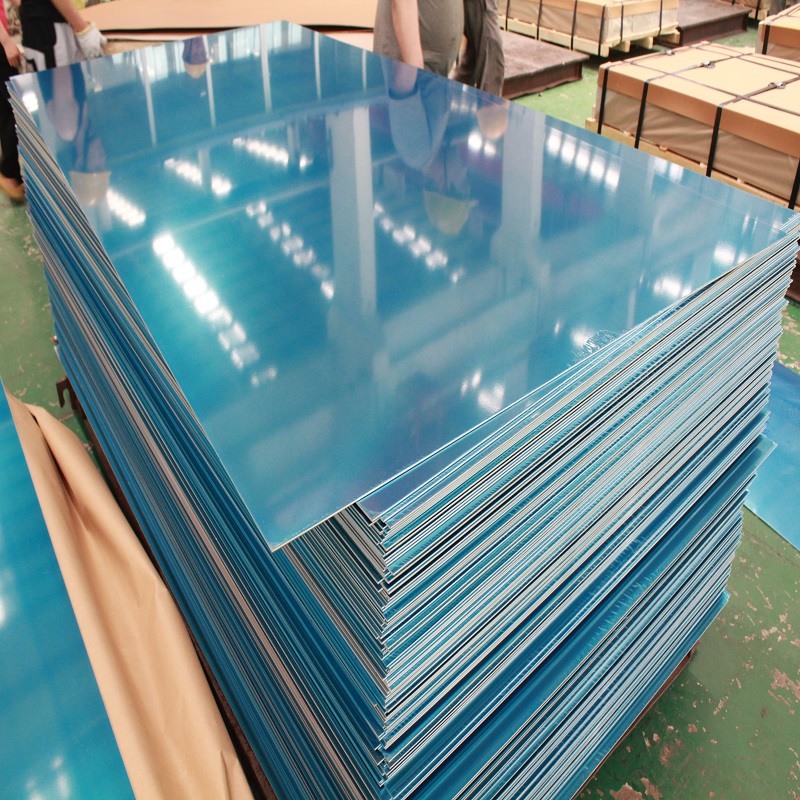

Aluminum pad printing cliches is a technique used in the pad printing process, ambayo ni njia ya kuhamisha picha au muundo kwenye uso.

Aluminum pad printing cliches is a plate or pad that is made from aluminum and has the desired image or design etched or engraved onto its surface. Cliché basi imefungwa na wino, Na pedi ya silicone imeshinikizwa kwenye nguzo, kuokota wino kutoka kwa maeneo yaliyowekwa.

Pedi ya silicone basi inasisitizwa kwenye uso ili kuchapishwa, Kuhamisha wino kwenye kitu unachotaka. Utaratibu huu unaruhusu uchapishaji sahihi na wa kina kwenye vifaa anuwai, pamoja na alumini.

Aluminum pad printing cliches are preferred in pad printing due to their durability, kwani wanaweza kuhimili matumizi ya kurudia bila kuvaa chini au kupoteza sura yao. Pia hutoa uhamishaji bora wa wino, kusababisha prints za hali ya juu.

Ili kuunda cliche ya alumini, Ubunifu au picha huundwa kwanza kwa digitali au inayotolewa kwa mkono. Ubunifu huo huhamishiwa kwenye mipako ya picha inayotumika kwa sahani alumini. Sahani hii iliyofunikwa imefunuliwa na taa ya UV, ambayo inafanya ugumu mipako katika maeneo ambayo picha iko.

Baada kuwepo hatarini, Mipako isiyozuiliwa imeoshwa, Kuacha nyuma ya utulivu wa muundo kwenye sahani ya aluminium. Sahani hiyo inatibiwa na suluhisho la kuzidisha ili kuongeza utulivu na kuhakikisha uhamishaji sahihi wa wino.

Aluminum pad printing plates play an important role in the printing industry and are favored mainly for their unique material properties and wide range of applications.

Characteristics of Aluminum pad printing cliches / aluminum pad printing plates

Good thermal conductivity: Aluminium, as a metal, has good thermal conductivity, which is particularly important in the pad printing process.

During the pad printing process, the pad printing oil needs to be dried before it can be completely transferred to the surface of the printed matter. The aluminum pad printing plate can speed up the drying speed of the pad printing oil through its efficient thermal conductivity, thereby improving pad printing efficiency.

High strength and stability: The aluminum pad printing plate / Aluminum pad printing cliches is not only light in weight, but also has high strength and stability, which allows it to maintain excellent performance in high-speed, large-volume printing production and reduce defects caused by material deformation or wear. Printing quality issues.

Flexible surface treatment: Aluminum pad printing plates have various surface treatments, which facilitate engraving and etching. This provides printing companies with a wider creative space and can produce more exquisite and complex prints.

Economical and practical: Compared with other materials such as stainless steel, aluminum pad printing plates are more economical in price. Wakati huo huo, their excellent performance can meet most printing needs, so they are very cost-effective.

Application of aluminum pad printing plate

Aluminum pad printing plates / Aluminum pad printing cliches are widely used in various printing fields, including but not limited to:

Logo and trademark printing: Pad printing technology is often used to print corporate logos, trademarks and other patterns on the surface of products. The aluminum pad printing plate ensures the clarity and consistency of the printed pattern with its high precision and stability.

Electronic product printing: In the manufacturing process of electronic products, aluminum pad printing plates are used to print text, symbols and other identification information on printed circuit boards. This information is of great significance for product assembly, testing and maintenance.

Packaging and decorative printing: Aluminum pad printing plates are also widely used in the printing of packaging materials and decorations, such as food packaging, cosmetic packaging, gift boxes, na kadhalika., to enhance the added value and attractiveness of products through exquisite printing patterns

What are the advantages and disadvantages of using Aluminum pad printing cliches in the printing industry?

Advantages

High precision: Aluminum pad printing cliches can transfer images and text to printing materials with high precision, ensuring the exquisiteness and clarity of printed matter. This is especially important for prints that require fine patterns and text, such as electronic product logos, cosmetic packaging, na kadhalika.

Stability and durability: Aluminum material has high strength and stability, which allows aluminum pad printing plates to maintain excellent performance in high-speed, large-volume printing production and reduce printing quality problems caused by material deformation or wear. Wakati huo huo, the service life of the aluminum pad printing plate is relatively long, reducing the frequency and cost of replacement.

Flexible surface treatment: Aluminum pad printing plates have various surface treatments, which facilitate engraving and etching. This provides printing companies with a wider creative space and can produce more exquisite and complex prints. Zaidi ya hayo, the aluminum pad printing plate can also be coated as needed to improve its corrosion resistance, wear resistance and other properties.

Economical and practical: Compared with other materials such as stainless steel, aluminum pad printing plates are more economical in price. Wakati huo huo, their excellent performance can meet most printing needs, so they are very cost-effective.

Environmental protection: Aluminum pad printing plates can be recycled and reused, which is in line with the current trend of environmental protection and sustainable development. During the printing process, using aluminum pad printing plates also helps reduce waste generation and environmental pollution.

Disadvantages

High skill requirements for operators: The printing process of aluminum pad printing plates requires operators to have high skills and experience to ensure printing quality and efficiency. If the operator’s skills are insufficient or the operation is improper, the quality of the printed matter may be reduced or the production efficiency may be reduced.

Maintenance cost: Although the aluminum pad printing plate has a long service life, it still requires regular maintenance and upkeep during use, such as cleaning, inspection, na kadhalika. These maintenance tasks require a certain amount of manpower, material and financial resources, which increases maintenance costs.

Limited scope of application: Although aluminum pad printing plates are used in many fields, their scope of application is still limited. Kwa mfano, on some special materials or printed materials with special requirements, other types of printing plates or printing technologies may need to be used.

Adaptability to inks and solvents: The adaptability of aluminum pad printing plates to inks and solvents may be subject to certain limitations. Different inks and solvents may have different effects on aluminum pad printing plates, such as corrosion, discoloration, na kadhalika. Kwa hiyo, when choosing inks and solvents, you need to consider their adaptability to aluminum pad printing plates.

Karatasi ya aluminium ya anodized ni bidhaa maalum ya chuma iliyotengenezwa kupitia athari ya umeme. Wakati wa mchakato wa uzalishaji, Karatasi ya alumini imewekwa kwenye elektroni inayolingana (kama vile asidi sulfuriki, asidi Chromic, oxalate, na kadhalika.) kama anode, na elektroni inafanywa chini ya hali maalum na hatua ya sasa ya nje.

Baada ya elektroni, Filamu ya oksidi ya alumini itaunda juu ya uso wa sahani ya aluminium. Unene wake kawaida ni kati ya 5 na 20 microns, Na filamu ngumu ya anodized inaweza kufikia 60 kwa 200 microns. Filamu hii ya oksidi sio tu inaboresha ugumu na kuvaa upinzani wa sahani ya aluminium, lakini pia huipa upinzani mzuri wa joto, Insulation na upinzani wa kutu.

Anodized karatasi ya alumini hutumiwa sana katika nyanja nyingi, ikiwemo ujenzi, Samani ya nyumbani, Elektroniki, sehemu za mitambo, Sehemu za ndege na gari, Vyombo vya usahihi na vifaa vya redio, Mashine za mashine, taa za taa, Elektroniki za Watumiaji, kazi za mikono, vifaa vya kaya, mapambo ya mambo ya ndani, Alama, samani, mapambo ya gari, na kadhalika.

|

daraja la

|

1050, 1060, 1070, 1100, 5050, 5052

|

|

Kumaliza uso

|

Rangi anodized Kioo cha kutafakari (Poda) Iliyofunikwa brushed (Anodized) Mchanga (Anodized) |

|

Rangi

|

Ecru, Black, Bluu, Dhahabu, Sliver, Red, Rose-dhahabu, kawaida

|

|

Saizi ya karatasi(mm)

|

330*625, 610*406, 1220*2440, CustMated

|

|

unene(mm)

|

0.3-10mm, kiwango: 0.5mm, 0.6mm, 0.8mm, 1.0mm, 2.0mm, na kadhalika

|

Karatasi ya aluminium iliyotolewa hutoa huduma na faida anuwai. Kwanza kabisa, ina upinzani mkubwa wa kutu na inaweza kupanua vizuri maisha yake ya huduma. Pili, kama nyenzo za msingi, Sahani ya alumini yenyewe ina upinzani mzuri wa moto na inaweza kuzuia kuenea kwa moto.

Zaidi ya hayo, anodized sahani aluminipia zina sifa za usindikaji mzuri, upinzani wa hali ya hewa, Nguvu ya metali yenye nguvu, Upinzani wenye nguvu wa doa na utumiaji mkubwa. Ni rahisi kuinama na kuunda na kufanya kukanyaga kwa kasi sana, na inaweza kusindika moja kwa moja kuwa bidhaa, ambayo hupunguza sana mzunguko wa uzalishaji wa bidhaa na gharama.

Wakati huo huo, Uso wake una ugumu wa hali ya juu, Upinzani mzuri wa mwanzo, Hakuna chanjo ya rangi, Huhifadhi rangi ya metali ya sahani ya alumini, na huongeza daraja na kuongeza thamani ya bidhaa.

Sisi ni muuzaji anayeongoza wa sahani za kuchapa pedi (clichés) Kwa mashine zote za kuchapa pedi. Tunasambaza aina kadhaa za sahani za kuchapa pedi:

- Laser Engravable Pad Uchapishaji sahani

- Pombe za kuchapa polymer pedi za polymer

- Maji yanayoweza kuosha polymer pedi za kuchapa

- Sahani za kuchapa pedi za chuma katika chuma nyembamba na nene

Sahani zetu zote zinaweza kutolewa kwa ukubwa wowote unaohitajika. na, ikiwa ni lazima, Imewekwa na mashimo yaliyopigwa kwa mashine yoyote ya kuchapa pedi kwenye soko.

-

-

-