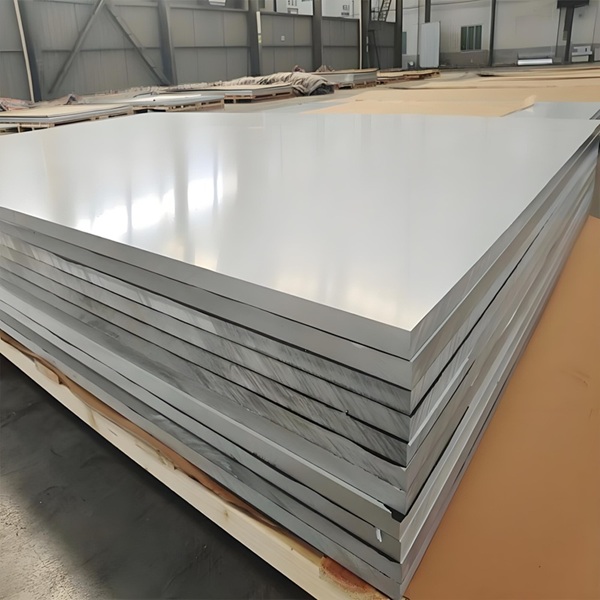

Opis

Aluminum Plate is a cornerstone material in marine engineering due to its unique combination of lightweight properties, odpornost proti koroziji, and strength. Among the most widely used alloys for marine applications are 5083, 5086, in 6061. This article explores their properties, differences, and suitability for marine environments.

Marine-grade aluminum alloys are designed to withstand harsh saltwater environments, resisting corrosion while maintaining structural integrity. Key requirements include:

- Saltwater corrosion resistance

- High strength-to-weight ratio

- Weldability and formability

- Resistance to stress corrosion cracking (SCC)

The 5xxx serija (magnesium-based) in 6xxx serija (magnesium-silicon-based) alloys dominate marine applications. Below, we compare 5083, 5086, in 6061.

aluminij Plate 5083: The Gold Standard for Marine Applications

Sestava:

- Primary Alloying Elements: 4–4.9% Mg, 0.4–1% Mn

- temper: Typically H116 or H321 (improved corrosion resistance).

Properties:

- Moč: High tensile strength (~290 MPa) and excellent toughness.

- Corrosion Resistance: Outstanding resistance to seawater and industrial chemicals.

- Varljivost: Excellent, retains strength after welding.

- Marine Applications:

- Ship hulls, krovi, and superstructures.

- Offshore platforms and buoys.

- Cryogenic storage tanks (due to low-temperature performance).

Advantages:

- Superior performance in aggressive marine environments.

- Ideal for load-bearing structures exposed to saltwater.

3. aluminij Plate 5086: A Close Contender

Sestava:

- Primary Alloying Elements: 3.5–4.5% Mg, 0.2–0.7% Mn

- temper: H116 or H321.

Properties:

- Moč: Slightly lower than 5083 but still robust (~270 MPa tensile strength).

- Corrosion Resistance: Excellent, comparable to 5083.

- Možnost oblikovanja: Better than 5083, making it easier to shape.

Marine Applications:

- Boat hulls and gangways.

- Marine railings and walkways.

- Pressure vessels and tankers.

Advantages:

- Cost-effective alternative to 5083 for moderately stressed components.

- Excellent balance of strength, odpornost proti koroziji, in uporabnost.

4. aluminij Plate 6061: The Versatile Structural Alloy

Sestava:

- Primary Alloying Elements: 0.8–1.2% Mg, 0.4–0.8% Si (heat-treatable).

- temper: T6 (solution heat-treated and artificially aged).

Properties:

- Moč: High tensile strength (~310 MPa) but less corrosion-resistant than 5xxx alloys.

- Obdelovalnost: Excellent, ideal for complex parts.

- Corrosion Resistance: Good in mild marine environments but may require protective coatings in harsh conditions.

Marine Applications:

- Fittings, masts, and hardware.

- Small boat components (e.g., frames, brackets).

- Non-immersed structures like cabin components.

Advantages:

- Superior machinability and weldability.

- High strength for structural parts not directly exposed to seawater.

5. Key Differences Between 5083, 5086, in 6061

| Lastnina | 5083 | 5086 | 6061 |

|---|---|---|---|

| Corrosion Resistance | Excellent (marine) | Excellent (marine) | dobro (needs coating) |

| Moč | visoka | Moderate-High | Very High |

| Primary Use | Ship hulls, offshore | Marine structures | Structural fittings |

| Varljivost | Excellent | Excellent | dobro |

| Cost | visoka | Moderate | Moderate |

6. Fabrication Tips for Marine Aluminum Plates

- Varjenje:

- Uporaba 5356 ali 5183 filler wire for 5xxx alloys.

- Avoid excessive heat to prevent magnesium segregation in 5083/5086.

- Corrosion Protection:

- Anodize or apply marine-grade coatings (e.g., epoxy) za 6061.

- Avoid galvanic corrosion by isolating aluminum from stainless steel or copper.

- Design Considerations:

- Use 5xxx alloys for immersed components.

- Opt for 6061 in low-corrosion, high-stress areas.

7. Sustainability and Recycling

- Aluminum is 100% recyclable, reducing environmental impact.

- Marine-grade alloys retain properties after recycling, supporting circular economy goals.

Choosing the right aluminum alloy for marine applications depends on balancing strength, odpornost proti koroziji, and cost:

- 5083/5086: Best for immersed, high-stress marine structures.

- 6061: Ideal for non-immersed, machined components.

For projects requiring direct seawater exposure, 5083 in 5086 are unmatched. Medtem, 6061 offers versatility for structural parts in less corrosive environments. Always consult with suppliers to ensure compliance with marine standards like ASTM B928 (for 5xxx alloys) ali AMS 4117 (za 6061).

-

-

-