Description

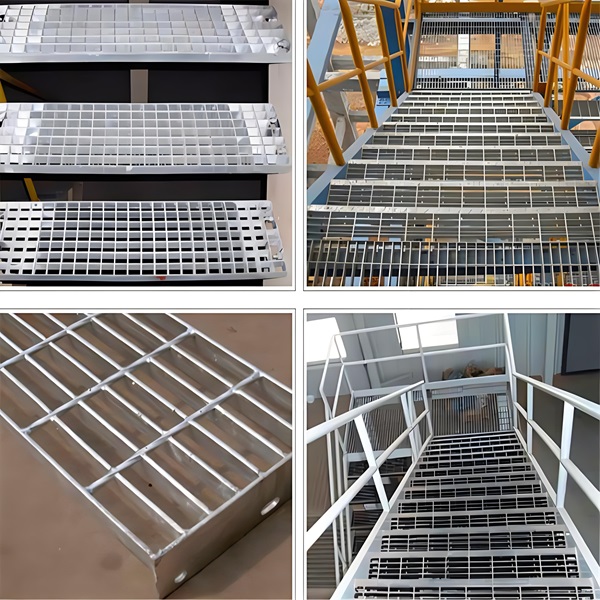

Aluminum dovetail grating is a type of metal grating made from aluminum alloy. It is designed with a unique dovetail shape that provides excellent slip resistance and stability. The grating is commonly used in industrial and commercial applications where safety and durability are essential.

Aluminum dovetail grating is lightweight, corrosion-resistant, and easy to install. It is ideal for use in areas where moisture, chemicals, and other harsh elements are present. The grating is available in a variety of sizes, shapes, and configurations to meet specific application requirements.

Some of the common applications of aluminum dovetail grating include:

1. Walkways and platforms

2. Stair treads

3. Drainage covers

4. Machine safety guards

5. Catwalks and mezzanine floors

6. Industrial flooring

Overall, aluminum dovetail grating is a reliable and cost-effective solution for various industrial and commercial applications. Its unique design provides excellent slip resistance, durability, and ease of maintenance, making it an ideal choice for many industries.

Specification for some aluminum grating bar

Bearing bar size: 1″ x 1/8″ to 2–1/2″ x 3/16″ with 1/4″ increments;

Bearing bar spacing (center-to-center): 1–3/16″, 15/16″, 11/16″ and 7/16″;

Cross bar spacing (center-to-center): 4″ or 2″.

Supported by I-shaped extruded bearing bars, swaged I-bar aluminum grating carries the same load as the swaged rectangular aluminum grating with lighter weight and less costs.

In addition, the striations at the top and bottom surfaces of the I bar increase the friction and provide high slip resistance performance.

Specification

Bearing bar size: 1″ x 1/4″ to 2–1/2″ x 1/4″ with 1/4″ increments;

Bearing bar spacing (center-to-center): 1–3/16″, 15/16″, 11/16″ and 7/16″;

cross bar spacing (center-to-center): 4″or 2″.

The Advantages of Aluminum Dovetail Grating

1. Lightweight: Aluminum dovetail grating is much lighter than steel grating, making it easier to handle and install.

2. Corrosion-resistant: Aluminum is naturally resistant to corrosion, making it an ideal material for outdoor or corrosive environments.

3. Low maintenance: Aluminum grating requires minimal maintenance compared to other materials, saving time and money in the long run.

4. High strength-to-weight ratio: Despite its lightweight nature, aluminum grating is strong and durable, able to support heavy loads without bending or warping.

5. Non-magnetic: Aluminum is non-magnetic, making it suitable for use in sensitive environments where magnetic interference is a concern.

6. Versatile: Aluminum dovetail grating can be customized to fit a variety of applications, including industrial, commercial, and architectural uses.

7. Cost-effective: While aluminum grating may have a higher initial cost compared to some materials, its long lifespan and low maintenance requirements make it a cost-effective choice in the long term.

Everything You Need to Know About Aluminum Grating

Aluminum grating is a type of grating that is made from aluminum. It is commonly used in industrial and commercial applications due to its durability, strength, and corrosion resistance. Here is everything you need to know about aluminum grating:

1. Types of Aluminum Grating: There are two main types of aluminum grating: welded and swage-locked. Welded aluminum grating is made by welding individual cross bars to the bearing bars.

Swage-locked aluminum grating is made by inserting cross bars into pre-punched holes in the bearing bars and then swaging the bars together.

2. Materials: Aluminum grating is made from aluminum alloy 6061-T6 or 6063-T6, which are both strong and corrosion-resistant.

3. Applications: Aluminum grating is used in a variety of applications, including flooring, walkways, stair treads, platforms, and catwalks. It is also used in industrial and commercial settings, such as oil and gas refineries, chemical plants, and food processing facilities.

4. Benefits: Aluminum grating is lightweight, easy to install, and requires little maintenance. It is also corrosion-resistant, which makes it ideal for use in harsh environments.

Additionally, aluminum grating is non-magnetic and non-sparking, which makes it suitable for use in areas where there is a risk of explosion.

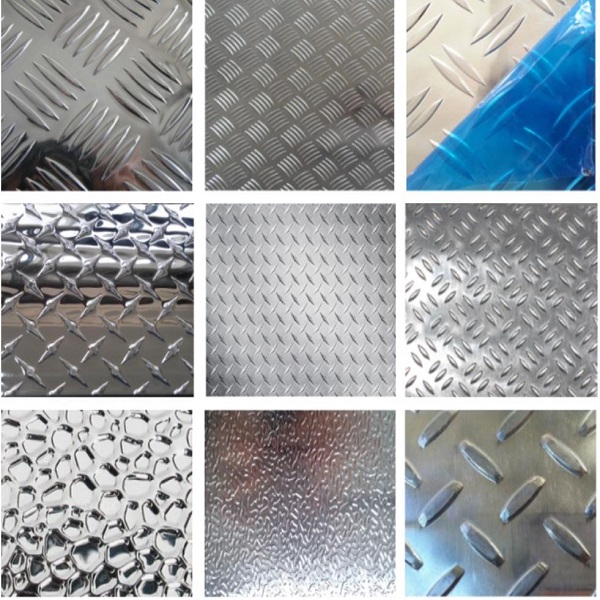

5. Finishes: Aluminum grating can be finished with a variety of coatings, including anodizing, powder coating, and paint. These finishes help to protect the grating from corrosion and enhance its appearance.

6. Load Capacity: The load capacity of aluminum grating depends on the size and spacing of the bearing bars and cross bars. It is important to select the appropriate grating for the intended application to ensure that it can support the required load.

Aluminum grating is a durable, corrosion-resistant, and lightweight material that is commonly used in industrial and commercial applications.

It is available in two main types, welded and swage-locked, and can be finished with a variety of coatings to enhance its appearance and protect it from corrosion.

When selecting aluminum grating, it is important to consider the load capacity and intended application to ensure that the appropriate grating is selected.

–

–

–