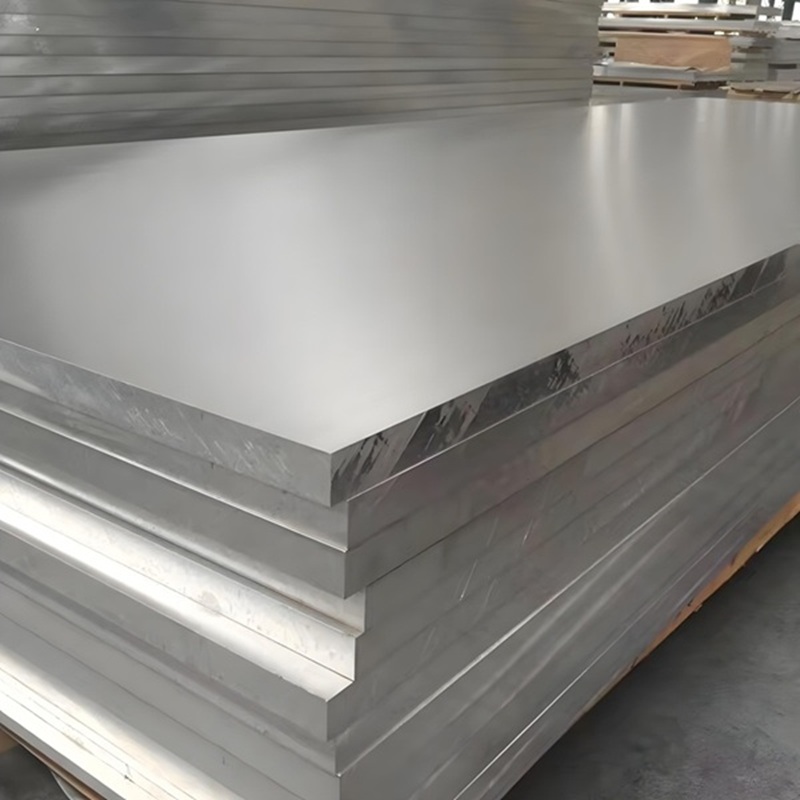

Description

5456 aluminum plate is a high-strength, corrosion-resistant aluminum-magnesium alloy plate, mainly composed of aluminum (Al), magnesium (Mg) and manganese (Mn) and other elements。

5456 aluminum alloy is a type of marine-grade aluminum alloy known for its excellent corrosion resistance, especially in saltwater environments. It’s widely used in applications where exposure to harsh conditions is expected, such as in boats, ships, and other marine structures.

Key characteristics of 5456 aluminum plate include:

1. Corrosion Resistance: High resistance to corrosion, making it ideal for marine applications.

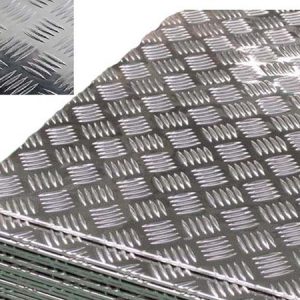

2. Formability: Good formability, which allows it to be easily shaped into various forms without cracking.

3. Weldability: Excellent weldability, allowing for easy joining of parts.

4. Strength: Moderate strength compared to some other alloys, but still strong enough for many applications.

5. Machinability: Fair machinability, meaning it can be worked on with standard machining tools.

The “5456” designation refers to the specific composition of the alloy, which includes magnesium (about 2.2-2.8%) and manganese (about 0.3-0.9%), among other elements. This combination gives the alloy its unique properties.

| Thickness | 0.2-6.0mm |

| Width | 100-2400mm |

| Length | 200-11000mm |

| Mother coil | CC or DC |

| Weight | About 2mt per pallet for general size |

| MOQ | 5ton per size |

| Protection | paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement. |

| Surface | clean and smooth, no bright speck, corrosion, oil, slotted, etc. |

| Standard product | GBT3880, JIS4000, EN485, ASTM-B209 |

| Delivery time | about 30days after receiving the deposit |

5456 aluminum plate has good plasticity and processability, and can be formed through extrusion, cold extrusion, rolling, milling and other processing processes to produce products of various shapes.

What are main applications of 5454 aluminum plate?

5456 aluminum plate is widely used and is mainly used in the following fields:

Ship and Marine Engineering: Used to manufacture hull structures, fuel tanks, bulkheads, etc., providing good anti-corrosion protection, and also suitable for offshore platforms, ocean buoys, etc.

Aerospace: Manufacturing aircraft casings, fuel tanks and other structural parts to ensure reliability and durability in harsh environments.

Automotive and Transportation: Used in automobile body structures, chassis parts, etc. to improve lightweight and fuel efficiency, and also used in railway vehicles and equipment.

High-pressure containers and explosion-proof equipment: Manufacturing high-pressure gas bottles, storage containers, etc., which are widely used in shell casings, explosion-proof equipment.

Chemical equipment: Manufacturing reactors, storage tanks, heat exchangers, etc. to ensure the stable operation of equipment in various chemical media.

–

–

–