Description

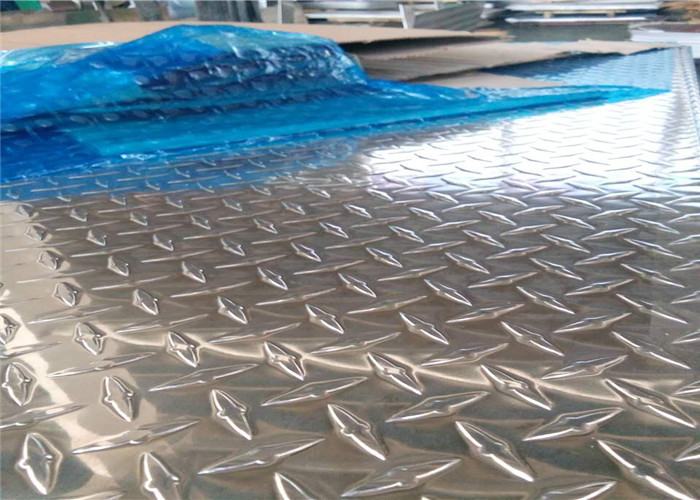

3003 aluminum checkered plate or Aluminum Tread Plate (or Checker Plate) is a smooth sheet with a regular diamond pattern or 3 bars or 5 bars pattern on one side. It is used for flooring, cladding, tool boxes, ramps or anything that requires an ultra-hard wearing property.

3003 aluminum checkered plate and 5052 aluminum tread plate is very general use tread plate during all aluminum alloy. Tread plate also called checkered plate or chequred plate.

Diamond tread plate is one of aluminum checkered plate, and it has bright or dull finish. Client from America is very interested in brigth finish diamond aluminum plate, so it is so called Brite plate or brite aluminum checker plate.

Aluminium tread plate is also commonly known as an aluminium checker plate and sometimes spelt ‘aluminium chequer plate’, an aluminium tread plate is a type of metal tread plate that has distinctive raised bars that give users a non-slip surface, making it super versatile for many industries.

There are some equivalent name of 3003 aluminum,and they are A3003, 3003a, aa3003, 3003aa, al3003, al3003a, a 3003, aa 3003, jis a3003p, al3003 class, aw3003, en3003 grade

3003 aluminum diamond plate with the raised tread pattern to improve traction. This is very commonly used for tool boxes, wall panels, flooring, truck bed liners and trim, garage and workshop outfitting, step plates and any other application that needs the light weight and strength of 3003 aluminum with increased traction of the raised tread pattern.

5052 aluminum is popular because it is one of the most versatile aluminum alloys. It is strong enough for fuel tanks, but adaptable enough for utensils.

Aluminum alloy 5052 has a smoother finish than 6061 Aluminum, although it is not heat-treatable. Aluminum 5052 has a higher fatigue strength and modulus of elasticity than Aluminum 6061, making it an excellent forming alloy.

Alloy 5052 Aluminum sheet is used in many types of industrial applications, including: Fuel tanks

Comparing with alloy 3003, In general, 3003 is fairly soft and has good corrosion resistance, good drawing, good workability, moderate strength, and is weldable, while 5052 is stronger and has better corrosion resistance, good drawing, good formability, higher strength, and also is weldable.

When annealed, aluminium alloy 5052 is stronger than 1100 and 3003 alloys. It is one of the higher strength, non-heat-treatable alloys and has good workability. It also has very good corrosion resistance, especially to salt water

Size of aluminum sheet

Thickness:0.2-6.0mm

Width:100-2400mm

Length:200-11000mm

Mother coil: CC or DC

Weight: About 2mt per pallet for general size

MOQ: 5-15 ton per size

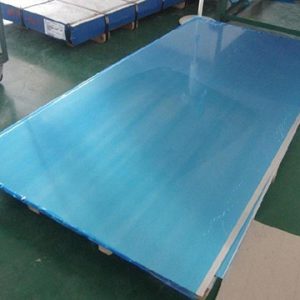

Protection: paper inter layer, white film, blue film, black-white film, micro bound film, according to your requirement.

Surface: clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Standard product: GBT3880, JIS4000, EN485, ASTM-B209

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of .063 aluminum diamond plate,1050 1060 1100 aluminum diamond/checker plate sheets manufacture,1050 1060 3003 Aluminum Diamond Sheet Plate for Anti-Slip Floor Manufacturer, Please send us your specifications and requirements, or feel free to contact us with any questions or inquiries that you may have.

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for 3003 aluminum checkered plate, We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

–

–

–