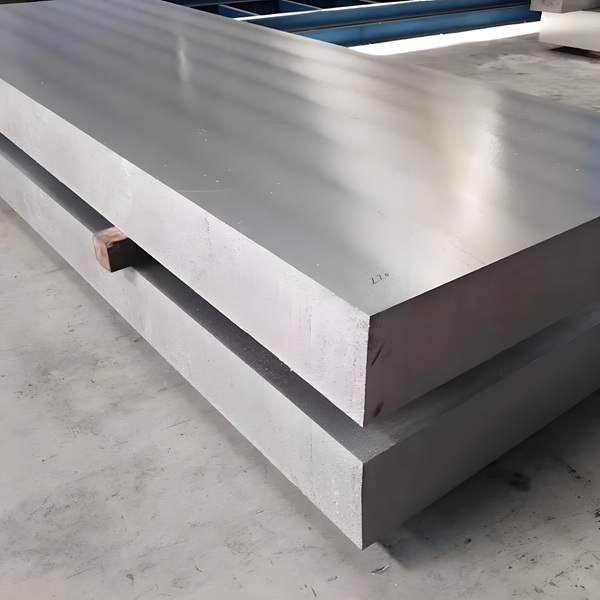

Descrizione

7050 aluminum plate is a high-strength heat-treatable alloy with extremely high strength, buone proprietà meccaniche e reazione anodica. It also exhibits excellent resistance to spalling corrosion and stress corrosion cracking.

Le proprietà meccaniche dei 7050 lastre di alluminio will be different after different heat treatment states (such as T7351, T7451, T7651, eccetera.)

Il 7050 T7451 Aluminum plate is a high – performance material that has gained significant traction across various industries due to its unique combination of properties.

I. 7075 T7451 Aluminum Plate Product Applications

Industria aerospaziale

- Fuselage Frames and Bulkheads: Il 7050 T7451 aluminum plate is extensively used in manufacturing fuselage frames and bulkheads. Its high strength – a – weight ratio is crucial in aircraft construction, as it helps to reduce the overall weight of the aircraft while maintaining structural integrity. This not only improves fuel efficiency but also enhances the aircraft’s performance. Per esempio, in commercial airliners, these components made of 7050 T7451 aluminum need to withstand significant stress during take – off, flight, and landing.

- Wing Skins: Wing skins are another critical application area. The material’s excellent resistance to stress corrosion cracking (SCC) and exfoliation corrosion is vital in the aerospace environment, where the wings are exposed to harsh weather conditions, including high humidity and temperature variations. Il 7050 T7451 aluminum plate ensures the long – term durability of wing skins, reducing maintenance requirements and costs.

Defense and Military Applications

- Military Vehicle Components: In the defense sector, 7050 T7451 aluminum is used in manufacturing components for military vehicles such as armored vehicles and military trucks. Its high strength allows these vehicles to withstand rough terrains and potential impacts, while its corrosion resistance ensures reliable performance in various environmental conditions, whether it’s in a desert or a humid jungle.

- Weapon Systems: It is also utilized in some weapon systems. The material’s ability to be machined precisely makes it suitable for components that require high – tolerance manufacturing, ensuring the proper functioning and accuracy of weapons.

alto – End Automotive Industry

- Performance Vehicle Parts: For high – performance cars, 7050 T7451 aluminum is used in parts like suspension components and engine brackets. The high strength of the material enables these parts to handle the high forces generated during high – speed driving and aggressive maneuvers. Allo stesso tempo, its lightweight nature helps to reduce the unsprung mass of the vehicle, improving overall handling and acceleration.

Industrial Machinery

- Heavy – Duty Equipment Components: In industrial machinery, 7050 T7451 aluminum plate is used in the production of components for heavy – duty equipment such as cranes and mining machinery. These components need to be strong to withstand heavy loads and corrosive environments (in the case of mining machinery, exposure to dust, moisture, and chemicals). Il 7050 T7451 aluminum plate’s combination of high strength and corrosion resistance makes it an ideal choice.

II. Specification Ranges

Spessore

The thickness of 7050 T7451 lastre di alluminio typically ranges from 1.0 mm to 600 mm. The wide range of thickness options allows it to be used in various applications with different load – bearing and structural requirements. Per esempio, thinner plates in the 1 – 10 mm range might be used for applications where weight is a primary concern and the load – bearing requirements are relatively low, such as in some interior aircraft components. D'altra parte, thicker plates, up to 600 mm, are suitable for applications in heavy – duty industrial machinery or large – scale aerospace structures that need to withstand extremely high loads.

Larghezza

The width of these aluminum plates usually spans up to 2000 mm. This width range provides flexibility in manufacturing processes. In the aerospace industry, wider plates can be used to fabricate large – scale components like wing skins without the need for multiple smaller pieces to be joined together, reducing the number of joints and potential weak points. In industrial applications, wider plates can be used to create larger – sized parts for machinery, streamlining the production process.

Lunghezza

The length of 7050 T7451 aluminum plates can reach up to 8000 mm. Similar to the width, longer plates are beneficial for manufacturing large – scale components. Per esempio, in the construction of fuselage frames, longer plates can be used to create continuous sections, enhancing the structural integrity and reducing assembly time. In industrial applications, long plates can be used for manufacturing components such as conveyor belts or large – scale storage tanks.

Il 7050 T7451 piastra di alluminio, with its diverse application areas and wide specification ranges, is a highly versatile and valuable material in modern manufacturing and engineering.

How does the 7050 T7451 aluminum plate compare to other aluminum alloys in terms of corrosion resistance?

-

-

-