Beskrivelse

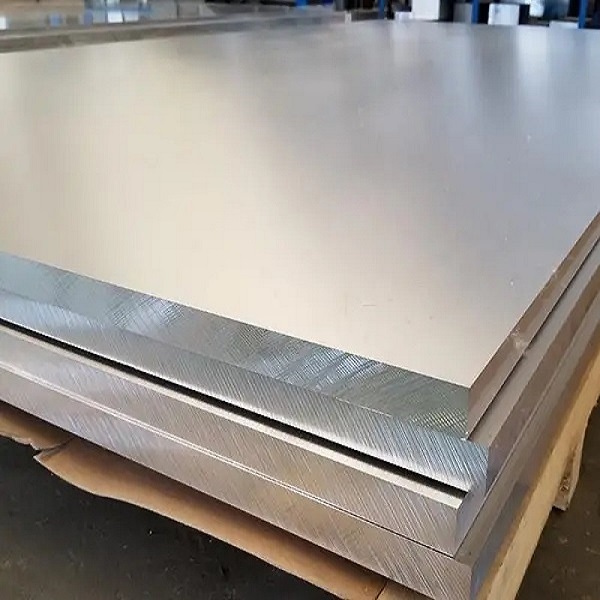

7075 T651 Aluminium Plate or UNS A97075 aluminium plate is a type of Al-Zn-Mg-Cu super-hard aluminum alloy known for its exceptional high strength, hårdhed, and excellent mechanical properties. It also exhibits good anodic reactivity. The presence of chromium enhances its resistance to stress corrosion cracking, while zinc imparts strength comparable to that of steel.

7075 aluminium Plade (AA7075) er en aluminiumslegering med zink som det primære legeringselement. Det har fremragende mekaniske egenskaber og udviser god duktilitet, høj styrke, sejhed, og god modstand mod træthed. Det har modereret formbarhed, når det er i den fuldt bløde, Annealet temperament og kan være varmebehandlet til styrkeniveauer, der kan sammenlignes med mange stållegeringer. Faktisk, karakter 7075 Aluminium er stærkere end mange typer mildt stål.

7075-T651 aluminiumplade has nearly double the strength-to-weight of grade 2 Titanium

7075 rumfart aluminium

Det 7075 Al legering foretrækkes mest af flyindustrien. Sammensætningen af denne specifikke Al -legering er 5,1–6,1% zink, 2.1–2,9% magnesium, 1.2–2,0% kobber og mindre end 0.5% af silicium, jern, mangan, Titanium, Chromium og andre sporemetaller

En af de vigtigste grunde til at overveje 7075 aluminium is for its high strength. Legeret med zink, Det er en af de stærkeste legeringer tilgængelige og stærkere end 6061. Men det tilbyder et lavere niveau af korrosionsbestandighed end 6061 og er også vanskeligere at svejse. 7075 bruges i marine, automotive, og luftfartsanvendelser, hvor styrke er meget høj prioritet. Det bruges også i en skydevåbenproduktion og bruges endda i hængende svæverammer

Aluminium Sheet / Plade 7075-T6/T651 bruges normalt til rumfart, militær, og bilapplikationer. 7075 aluminium er det stærkeste aluminium, med styrken af mange stål, Mens han bevarer aluminiums lette kvaliteter og korrosionsbestandighed.

| Legering | Temperament | Tykkelse | Bredde |

| 7075 | T651 | 4-260mm | 1200-3800mm |

| 7075 | T7651 | 4-260mm | 1200-3800mm |

| 7075 | T7351 | 4-260mm | 1200-3800mm |

Mechanical properties

| Legeringstilstand | Retning | Tykkelse (mm) | Trækstyrke | flydespænding | Brudforlængelse | Standard |

| 7075-T651 | LT | 6-260 | 570-590Mpa | 495-515Mpa | 10-13.5 | GB/T3880 |

| 7075-T7651 | LT | 6-102 | 550-560Mpa | 480-490Mpa | 10.5-12.5 | AMS4045K |

| 7075-T7351 | LT | 6-102 | 500-520Mpa | 420-435Mpa | 10-12.5 | AMS4078 |

Aluminium 7075 is a member of the 7000 serie, which has zinc as its main alloying component and is well known for its extraordinarily high strength. Tempering treatment can then further enhance its high mechanical strength. This property makes alloy 7075 very popular in the aerospace and defense industries.

| Typical Mechanical Properties of 7075 aluminiumsplade | ||||

| Temperament | Tykkelse

(mm) |

trækstyrke

(Mpa) |

flydespænding

(Mpa) |

Forlængelse

(%) |

| T6 | 1~3.2 | 540 | 470 | 8 |

| T6 | 3.2~6.3 | 540 | 475 | 8 |

| T651 | 6.3~12.5 | 540 | 460 | 9 |

| T651 | 25~50 | 530 | 460 | — |

| T651 | 60~80 | 495 | 420 | — |

| T651 | 90~100 | 460 | 370 | |

Its strength is comparable to that of many types of steel, but it has a much lower density. The alloy is an excellent substitute to steel in high-stress applications. It also excels in withstanding fatigue stress, rendering it very reliable, a quality much sought after in the industries mentioned above.

Legering 7075 offers only average corrosion resistance, an outcome of the small amount of copper included in its chemical composition. It also features reasonable machinability and poor forming and weldability. Another drawback of this alloy is that it has a comparatively high-cost relative to other aluminum alloys due to its exceptionally high strength.

RAYIWELL MFG or RuiYi Aluminum provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting the challenges of the future.

Quality could full meet AMS aviation standard.

Standard

Bare: AMS QQ-A-250/12, BS 2 L95, AMS 4038, AMS 4045, AMS 4039, AMS 4049, AMS 4044, AMS 4045, AMS 4078, QQ-A-250/24, AIR 9048.690, AIR 9048.700, AIR 9048.710, AIR 9049, etc.

AlClad: AMS QQ-A-250/13, BS 2 L88, AMS 4046, AMS 4048, AMS 4049, QQ-A-250/18, QQ-A-250/25, QQ-A-250/26, etc.

We have passed AS9100, OHSAS 18001 and other certifications required by the aviation industry, providing a strong guarantee for the quality of aerospace materials produced by our company.

Accreditations

AS9100

OHSAS 18001

ISO14001

ISO9001

NADCAP HT

NADCAP NDT

IATP16949

-

-

-