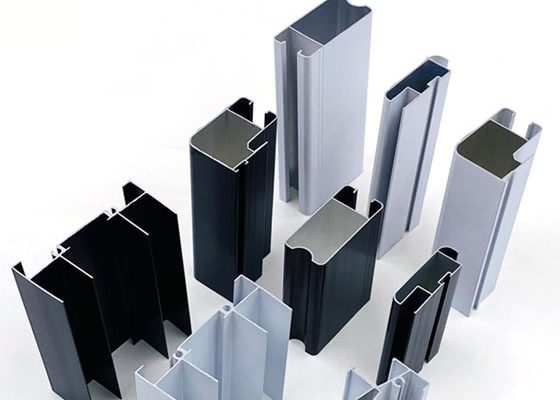

Aluminium extrusion profile for doors and windows is a kind of door and window frame decoration building material made of aluminum alloy as raw material. Its advantages are good wind pressure resistance and non-combustibility, and it is a recognized flame-retardant material.

Aluminum alloy doors and windows refer to doors and windows made of aluminum alloy extruded profiles as frames, stiles, and fans. They are called aluminum alloy doors and windows, or aluminum doors and windows for short. Aluminum alloy doors and windows include doors and windows made of aluminum alloy as the base material of the force-bearing member (the member that bears and transmits its own weight and load), and wood and plastic composites.

The production process of aluminum alloy door and window profiles includes three major processes: smelting, extrusion molding, og farvelægning. The coloring process includes three options: anodic oxidation, air oxidation, and fluorocarbon painting.

1. Melting is the primary process in the production of aluminum alloy door and window profiles

1. Raw materials, according to the actual aluminum alloy profiles that need to be produced, calculate the amount of various aluminum alloy components added, and effectively match various raw materials;

2. Smelting: The selected raw materials are added to the melting furnace for melting according to the processing technology regulations, and the slag and gas in the melt are reasonably removed according to the degassing and slagging refining methods;

3. Forging: Under certain forging process standards, the smelted aluminum liquid can be turned into round casting rods of various specifications and models after water cooling according to the deep water well forging system software.

Extrusion molding is carried out on an automatic production line consisting of ingot heating, extrusion, cooling, tension straightening, sawing and other processes.

The equipment on the production line includes induction heating furnace, extrusion machine, furnace table, discharge conveyor, profile lifting and transferring device, cooling bed, tension leveler, storage table, tractor, sawing machine, etc.

1. Induction heating furnace, the heating temperature of the ingot is generally controlled at 400 ° C ~ 520 °C, if the temperature is too high or too low, it will directly affect the extrusion molding. The extrusion machine generally adopts a single-action hydraulic press, and its tonnage is between 1200 tons and 2500 tons.

2. The diameter of the extrusion cylinder of the extrusion machine varies with the tonnage of the extrusion machine. The larger the tonnage of the extrusion machine, the larger the diameter of the extrusion cylinder.

The diameter of the extrusion cylinder is generally in the range of 150mm~300mm. The working temperature of the extrusion tool is 360°C~460°C, and the extrusion speed is 20 m/min~80m/min. Extrusion tools mainly include dies. Extrusion dies are divided into flat dies, split dies, tongue dies and splitter combined dies according to their structural characteristics. The production of aluminum alloy door and window profiles mostly uses flat dies and split split dies.

3. The discharge table receives the profile extruded from the extruder and transfers the profile to the discharge table. Most of the discharge workbench is a horizontal strip transport model, and the movement speed of the horizontal strip is synchronized with the extrusion speed.

4. The cooling bed is mostly of walking beam type, and a considerable number of fans are installed below to ensure uniform cooling of the profiles, so that the temperature of the profiles is lower than 70°C before straightening.

5. The tension straightening machine is equipped with torsion jaws, which can stretch and straighten while torsion correction. After the tension leveler is the material storage table, which provides profiles to the sawing machine table, and the sawing machine cuts the profiles according to the fixed length.

Coloring treatment of aluminum alloy door and window profiles

The surface treatment of aluminum alloy door and window profiles is mostly anodized to make the surface of the profiles silvery white. Surface treatment can enhance the profile appearance and prolong the service life of aluminum door and window profiles.

Anodizing process flow: loading→degreasing→water washing→alkali etching→warm water washing→cold water washing→neutralizing light→water washing→anodizing→cold water washing→warm water washing→sealing→drying→unloading→finished product inspection→packing The thickness of the oxide film after anodic oxidation of aluminum door and window profiles is not less than 10 μm.

The surface treatment of aluminum door and window profiles can also be colored. Aluminum profiles that require other colors can be obtained by natural oxidation coloring, electrolytic coloring and dipping coloring.

6061 6063 Aluminiumsprofiler producent RAYIWELL MFG fra Kina. Aluminiumsprofiler kan opdeles i 1024, 2011, 6063, 6061, 6082, 7075 and other alloy grades of aluminiumsprofiler, af hvilken 6 serie er den mest almindelige. Forskellen mellem forskellige kvaliteter er, at forholdet mellem forskellige metalkomponenter er forskelligt, undtagen almindeligt anvendte aluminiumsprofiler til døre og vinduer Udover arkitektoniske aluminiumsprofiler som f.eks. 60 serie, 70 serie, 80 serie, 90 serie, og gardinvæg-serien, der er ingen klar model skelnen for industrielle aluminiumsprofiler, og de fleste producenter behandler dem i henhold til de faktiske tegninger af kunder.

Ekstruderet aluminiumsprofil fremstilles ved at skubbe aluminiumsstykker gennem en metalmatrice for at få standard- eller brugerdefinerede former. Vi kan producere ekstruderede profiler med vægten pr. meter fra 0.10 Kg op til 50 Kg, den største cirkelstørrelse er op til 650 mm til industrielle applikationer. Med egen overfladebehandlingskapacitet, alle vores aluminiumsprofiler kan fremstilles i møllefinish, anodiseret eller pulverlakeret i ønskede farver.

Aluminiumsekstruderingsprofiler bruges mest i bygge- og møbelsektoren, inden for bilindustrien og i transportbranchen. Vi kan nævne, for eksempel, aluminiumskanter med skruebeslag, afløb og vandafvisere, glasekstruderinger, billedrammer, trimprofiler til køretøjer, hjørneelementer med specielle sektioner, aluminiumshåndtag og gelændere