Description

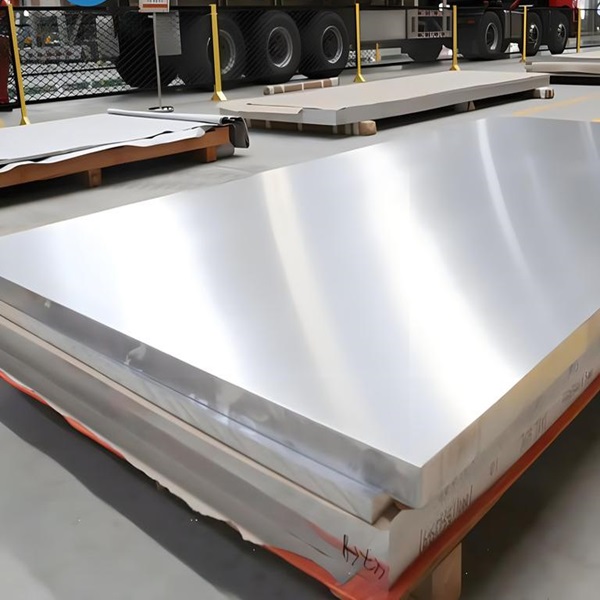

Aerospace aluminum plates and aluminum rods are commonly used materials in the aerospace field and have the characteristics of high quality and high performance.

Aerospace aluminum plate is a high-strength, high-hardness aluminum plate, usually made of 7 series aluminum alloy, such as 7075 aluminum alloy.

The surface treatment of aerospace aluminum plate usually uses anodizing or spraying technology to improve its corrosion resistance and appearance quality but depends on customer’s specific request.

Aerospace aluminum plates are lightweight, high-strength, high-rigidity and high-durability, and can withstand extreme temperatures and pressures, so they are widely used in the aerospace field.

Aerospace aluminum rods are also a commonly used aviation material, usually made of 6 series or 7 series aluminum alloy, such as 6061 aluminum alloy.

This aluminum rod has high strength, high rigidity and good processing properties, and can meet the high requirements of the aerospace field.

Aviation aluminum rods are mainly used to manufacture aircraft parts, engine parts and aerospace vehicle structural parts.

Aviation aluminum plates and rods need to be of high quality and high performance, and require strict quality control and performance testing during the production process.

At the same time, the surface treatment and processing technology of aviation aluminum plates and aluminum rods also need to meet high standards to ensure that their appearance quality and performance meet requirements.

Aviation aluminum alloy is an aluminum alloy material specially developed for the aviation industry. It has the characteristics of high strength, high rigidity, light weight and corrosion resistance.

Due to its excellent performance in extreme environments such as high temperature, high stress and high corrosion, aviation aluminum alloy has been widely used in the aviation industry.

Aviation aluminum alloys have higher strength and rigidity than ordinary aluminum alloys, while maintaining good plasticity and processing properties.

In addition, aviation aluminum alloys also have good corrosion resistance and fatigue resistance, and can maintain their performance for a long time under complex environmental conditions.

Common aviation aluminum alloys include 7 series aluminum alloys and 6 series aluminum alloys.

7 series aluminum alloy is a high-strength, high-hardness aluminum alloy, such as 7075 aluminum alloy, which is mainly used to manufacture important structural parts such as aircraft frames and skins.

6 series aluminum alloy is a medium-strength, medium-hardness aluminum alloy, such as 6061 aluminum alloy, which is mainly used to manufacture aircraft parts and engine parts.

The production of aviation aluminum alloys requires multiple processes, including smelting, casting, rolling, heat treatment and surface treatment.

During the production process, strict quality control and performance testing are required to ensure that the quality and performance of aviation aluminum alloys meet the requirements.

At the same time, the surface treatment of aviation aluminum alloy is also very important, which can improve its corrosion resistance and appearance quality.

Aerospace aluminum alloys are available in a variety of grades and states, depending on their manufacturing standards and uses. The following are some common aviation aluminum alloy grades and states:

7075 aluminum alloy is a high-strength, high-hardness aluminum alloy widely used in the aerospace field. It has excellent mechanical properties, corrosion resistance and fatigue resistance.

7075 aluminum alloy can be heat treated in different states such as T6 and T73 to improve its overall performance.

6061 aluminum alloy is a medium-strength, medium-hardness aluminum alloy that is also widely used in the aerospace field. It has good plasticity, welding performance and processing performance.

6061 aluminum alloy can be heat treated in different states such as T4 and T6 to improve its hardness and mechanical properties.

Typical Application of Aviation aluminum Plate:

| Item | Grade | Temper | Application |

| 1 | 2024 | O,T351,T851 | Fuselage structure, wing tensile component, shear web, stiff structure section |

| 2 | 2014 | T851,T351 | Fuselage machining component, bulkhead, wing skins and other structure component for high performance military aircraft |

| 3 | 2324 | T39 | Lower wing skins and wing box component for commercial aircraft |

| 4 | 7050 | T7651,T7451 | fuselage ring, frame |

| 5 | 7150 | T6151,T7751 | Upper wing skins for large commercial airplane which requires resistant to high pressure, upper wing reinforce plate and lower horizontal stabilizer panel for civil and military aircraft |

| 6 | 7055 | T7751 | Upper wing structure, horizontal stabilizer, keel beam, seat track, freight slide track |

| 7 | 7075 | T651, T7651,O,T7351 | Airplane structure component required high strength, moderate toughness and moderate corrosion resistance |

| 8 | 7475 | T651,T7351 | Fuselage skin, wing skin, wing spar, fuselage bulkhead |

What are main Application of aluminum alloy in aviation field?

Aluminum alloy, as a lightweight, high-strength, corrosion-resistant metal material, has been widely used in the aviation field.

1. Aircraft structure

Aluminum alloys are widely used in aircraft structures, including fuselages, wings, tails, etc. Aluminum alloy has high specific strength, processing performance and corrosion resistance, and can meet the material requirements of aircraft structures.

The main form of aluminum alloy aircraft structure is the welded structure of aluminum alloy plates and profiles, which has the advantages of light weight, high strength, and corrosion resistance.

2. Landing gear

Landing gear is an important part of the aircraft and requires materials with high strength, corrosion resistance and good processing properties.

As an excellent metal material, aluminum alloy is widely used in landing gear manufacturing.

The main form of aluminum alloy landing gear is cast integral landing gear, which has the advantages of light weight, high strength, and corrosion resistance.

3.Engine parts

Aluminum alloys are also widely used in aerospace engines, including turbine blades, compressor blades, discs, etc.

Aluminum alloy has the advantages of high strength, corrosion resistance and good thermal conductivity, and can meet the material requirements of engine parts.

The main forms of aluminum alloy engine parts are casting and machining, which have the advantages of light weight, high strength, and corrosion resistance.

4.Aerospace components

Aluminum alloys are also widely used in aerospace components, including satellite structures, rocket fuel tanks, etc.

Aluminum alloy has the advantages of high strength, corrosion resistance and good processing properties, and can meet the material requirements of aerospace components.

The main form of aluminum alloy aerospace components is the welded structure of aluminum alloy plates and profiles, which has the advantages of light weight, high strength, and corrosion resistance.

5.Aviation foil

Aviation foil is an aluminum alloy foil with a thickness less than 0.2mm. It has the advantages of high strength, light weight, and corrosion resistance.

Aviation foils are mainly used as skin materials and structural materials in aircraft manufacturing, which can improve the performance and life of the aircraft.

The main form of aviation foil is aluminum alloy rolled foil, which has the advantages of light weight, high strength and corrosion resistance.

In short, aluminum alloys are widely used in the aviation field, including aircraft structures, landing gears, engine parts, aerospace components and aviation foils.

Aluminum alloy has the advantages of high strength, light weight, and corrosion resistance, and can meet the material requirements of the aviation field.

In the future, with the continuous development of aviation technology, the application of aluminum alloys in the aviation field will be more extensive and in-depth.

RAYIWELL MFG is a professional supplier of metal materials in China, and we can supply aluminum, stainless, galvanized steel, cold rolled steel, coated aluminum, copper plate, we are only cooperated with number 1 manufacturer in China to make our customer happier and satisfied with our quality but not only competitive price.

–

–

–